Welding Rotators

|

|

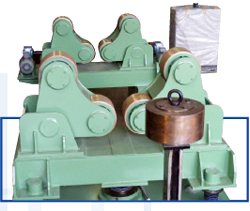

We manufacture high quality rotators which are being used with various processes such as SAW/ TIG/

MIG/ ARC/ etc., capacities upto 2000 Tons. Steel rollers or polyurathene lined rollers are provided as per application. For higher capacity rotators forged rollers are provided.

• Our Standard Rotators consists of drive and idler unit. The frame and roller brackets are fabricated with

heavy sections, relieved and precision machined.

• Overload disc to protect polyurethane roller.

• Steplessely variable surface speed from 75 to 1500 mm/min.or higher and controlled through AC

Variable frequency drives. For precision movement encoder feedbacks are provided on case basis.

• Forward/ reserve rotation and emergency stop facility on panel.

• Operator pendant with forward/ reverse inch or run speed variation and stop functions.

|

|

Application |

Welding of Pipes, API pipes, Boilers, Heat Exchangers, Pressure Vessels, Mounted

Vessels, LPG ullets, Barrels, Tanks etc. |

| |

Advantages |

• An indispensable tool for shell fabrication shops.

• Attains exceptional quality circumferential joints on shells.

• Increased production with reduced labour skill.

• Leads to minimum Shell/ Job handling.

• lesser usage of crane reduces idle time.

• Improves plant efficiency.

• Welding automation. |

| |

SPECIFICATIONS FOR SELF CENTERING ROTATOR

|

MODEL |

SCR

5 |

SCR 10 |

SCR 20 |

SCR 30 |

SCR 40 |

SCR 50 |

SCR

80 |

SCR 100 |

SCR 120 |

SCR 150 |

SCR 200 |

SCR

300 |

SCR

500 |

CAPACITY- DRIVE & IDLER(TONS) |

5 TONS |

10 TONS |

20 TONS |

30 TONS |

40 TONS |

50 TONS |

80 TONS |

100 TONS |

125 TONS |

150 TONS |

200 TONS |

300 TONS |

500 TONS |

SPEED RANGE

(mm/min) |

150-1250 |

150-1250 |

150-1250 |

150-1250 |

150-1250 |

150-1250 |

150-1250 |

150-1250 |

150-1250 |

150-1250 |

150-1250 |

150-1250 |

150-1250 |

VESSEL(min-max) (mm) |

400-4000 |

400-4000 |

400-4500 |

500-5000 |

500-5000 |

500-5000 |

600-6000 |

600-6500 |

800-6500 |

900-7000 |

900-7000 |

1000-7500 |

1200-8500 |

ROLLER DIAMETER

(mm) |

250 |

250 |

300 |

400 |

400 |

400 |

500 |

500 |

500 |

600

(Forged) |

600

(Forged) |

600

(Forged) |

700

(Forged) |

ROLLER WIDTH (mm) |

75 |

100 |

125 |

150 |

150 |

200 |

200 |

200 |

200 |

250 |

250 |

300 |

300 |

|

| |

There Are Two Main Categorizes Of Rotators : |

|

|

|

The Self Centering Types :- Model 'SCR'- SERIES |

|

Construction of machine is similar to that of conventional type Rotators. However, Housing Brackets

are supported directly on the machine bed and are attached to the bed only with an L.H./ R.H. lead

Screw andnuts. When the leadScrew is rotated with the ratchet handle, the Roller Brackets move

simultaneously towards each other or away from each other. |

|

In this series there will be twin drive

arrangement. This type of design provides simultaneous and step less adjustment of the

Roller housings, and keep the job axis atways at the same position irrespective

of diameter setting. |

| |

|

The Self Aligning Types :- Model 'SAR' - SERIES |

|

Self Aligning Rotators automatically adjust the Roller Housings to accept any job diameters within

specified diameter range. This type of machines are generally used to cope with the change in shell

diameter, job to job. The roller housings of this type of machine are hinged to the beds and open automatically when larger diameter job is introduced. In

this type of rotator. each roller bracket assembly has two separate roller assemblies,and thus

supports the job on wider area.The final drive is given to both the 2-sets of rollers of the Drive

Unit, provide better traction to the job. However,in this case a declutching arrangement is provided

to the top rollers,in order to protect the gear boxes, as when the job hits the top rollers first

while loading, there is a tendency of rotating the top rollers where as it is locked by the gear

boxes. |

|

| |

|

SPECIFICATIONS FOR SELF ALIGNING ROTATOR |

MODEL |

SAR

5 |

SAR 10 |

SAR 20 |

SAR 30 |

SAR 40 |

SAR 50 |

SAR

80 |

SAR 100 |

SAR 120 |

SAR 150 |

SAR 200 |

SAR

300 |

SAR

500 |

CAPACITY- DRIVE & IDLER(TONS) |

5 TONS |

10 TONS |

20 TONS |

30 TONS |

40 TONS |

50 TONS |

80 TONS |

100 TONS |

125 TONS |

150 TONS |

200 TONS |

300 TONS |

500 TONS |

SPEED RANGE

(mm/min) |

150-1250 |

150-1250 |

150-1250 |

150-1250 |

150-1250 |

150-1250 |

150-1250 |

150-1250 |

150-1250 |

150-1250 |

150-1250 |

150-1250 |

150-1250 |

VESSEL(min-max) (mm) |

300

-2500 |

400-3000 |

500-4000 |

500-5000 |

600-5000 |

600-5000 |

900-6000 |

900-6000 |

1000-6500 |

1000-7000 |

1200-7500 |

1400-7500 |

1600-8000 |

ROLLER DIAMETER

(mm) |

250 |

250 |

300 |

400 |

400 |

400 |

500 |

500 |

500 |

500

|

500

(Forged) |

600

(Forged) |

600

(Forged) |

ROLLER WIDTH (mm) |

50 |

100 |

150 |

150 |

150 |

150 |

150 |

175 |

175 |

200 |

250 |

300 |

300 |

|

| |

|

Anti Drift System |

|

During C-seam welding of shell sections on rotators,axial movement of shell or shell

drifting invariably takes place.This drifting cannot be avoided. Reasons for this drifting could be geometrical inaccuracies of individual

shells.inaccuracies of drive unit and idler unit alignment,etc. Even if the drive unit and idler

units are aligned witheach otherinitially, duringshell loading,the algnment tends to get disturbed.

In lighter shells. this drifting can be stopped by positive stoppers. However in heavier shells. due

to axial drifting,tremendous pressure will get generated and this pressure will come on the

positive stopper, if provided, and will break it. Ideal solution is to prevent this happening, to

avoid creating such situation. This is achieved through anti-drifting arrangement. |

|

| In this case

also, drifting will take place which cannot be avoided. But the movement will be restricted within

a band of "+ 1- 5 mm". Seam will keep floating forward and backward within this range. |

|